Client Introduction

A global provider of Life Science products and innovative solutions for Pharmaceutical, Nutritional, Agrochemical, and Industrial customers, our client offers innovative, cost-effective and high-quality products and solutions tailored to meet the needs of a wide range of industries.

Problem Statement

- The lack of a centralized database and the inability to analyze data in real time proved to be a major roadblock to achieve industrial excellence.

- Due to the absence of a self-driven Industry 5.0 tool, it was almost impossible to visualize and optimize the power plant’s performance, and calculation of efficiency in real-time was not possible without an Industry 4.0 solution.

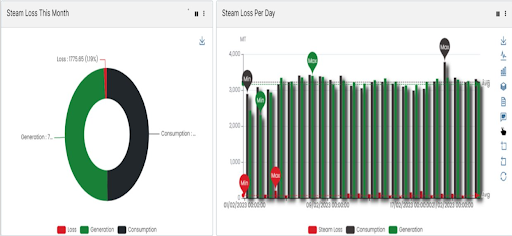

- Since no IoT solution was available, it was impossible to monitor steam production, consumption, electricity generation, and loss calculation in real time.

- An analysis of the root cause of the efficiency drop, and the steam loss was not possible prior to our introduction.

- The lack of system-generated reports contributed significantly to the time required by operators to prepare numerous reports and logbooks.

- Preventive maintenance and alerts for critical equipment such as ID Fan, FD Fan, Boiler feed pump, and Turbine were not available.

Solution

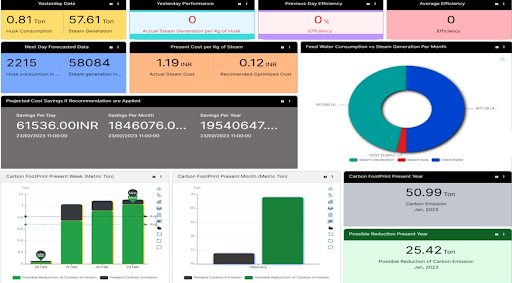

- A central cloud storage platform with UnifyTwin’s Intelligent Industrial App Suite platform for real-time data visualization and analysis.

- In order to understand the status of all assets, a digital twin of all assets was created.

- Calculation and visualization of boiler and turbine efficiency in real-time to understand the equipment status.

- Monitoring the performance of critical assets such as the economizer, the HP heater, and so forth in order to identify the reasons for the drop in efficiency.

- Monitoring steam flow throughout the steam distribution network as well as real-time visualizations of steam generation and consumption to determine where energy is being lost.

- An automated system generated logbook and reports to ensure 100% data transparency, as well as a controllable parameter range recommendation to achieve optimal performance.

- An early warning system is in place to prevent the unwanted breakdown of any critical assets.

Business Benefits

- Boiler efficiency improved upwards of ~5%.

- Total of 9-12% cost savings was achieved.

- Boiler performance rating(steam kg per kg of fuel ) improved up to 4.25 on 5.

- Improved levels of worker & environment safety achieved.

- Cost savings of ~ $200K per annum.

Conclusion

With our Intelligent App Suite, Industries can now operate more efficiently, achieve higher quality production, and improve safety while embarking on their path to Digital Transformation. For more information about our solution offerings, contact us at

sales@knowledgelens.com