“As per a recent Gartner study, AI Enabled Vision Analytics is one of the key technology disruptors that will mature by 2023. Business stakeholders must now identify new business models and areas of engagement in order to leverage their information assets and enable transformative impact.

New Business Demands

In today’s rapidly evolving marketplace, there is a renewed demand for AI Enabled tech solutions that can leverage businesses’ growing digital, visual and informational assets.

Being a reputed tech solutions provider in the Big Data and AI space over the last 7 years, Knowledge Lens has worked closely with several industry leaders on their Digital Transformation journey.

Our AI Enabled Vision Analytics solution, currently powers Retail, Manufacturing, Pharma and Logistics industries across the globe.

For organizations exploring the potential of AI Enabled Vision Analytics, there is a wealth of opportunities in the following three areas:

- Regulatory Enforcement,

- Physical Security, and

- Process Improvement.

Here’s presenting our customer case study on Cement Bag

Detection & Counting for one of India’s leading Indian Cement Manufacturers-

Client Introduction & Business Requirement:

Cement Plants in India, the Middle East and other countries have a large production and construction demand; the cement is packed and shipped in plastic or paper bags. Dispatches to warehouses, depots and customer sites require efficient and reliable logistics handling of loading, counting, weighing and dispatching of cement bags.

Some of the biggest plants today dispatch an average of 3 metric tonnes of cement per month, packed into 1 Lakh bags from just ONE plant, with more than 1000 trucks plying per day. To achieve these mammoth numbers in a smooth and reliable manner, the plant personnel must be assisted by intelligent systems to reduce missed counts, rejects, fraud and minimize losses.

While Plants have tried and tested the IR sensor based, Load cell enabled & Manual operator driven methods, the accuracy levels have been less than 95%.

Additionally, there are count mismatches, recounting needed at packing points, loading points and several man hours needed to reconcile across floor operators’ manual books or non-integrated systems, with their ERP systems to track the fulfilment of customer’s purchase orders.

Our client, a leading Indian Cement Manufacturer wished to eliminate manual or inaccurate semi-automatic processes of loading, counting and dispatching of bags. There was a need for reliable, AI powered logistics handling of loading, counting, weighing and dispatching of cement bags at their plant to reduce missed counts, rejects, fraud and losses.

Solution Overview:

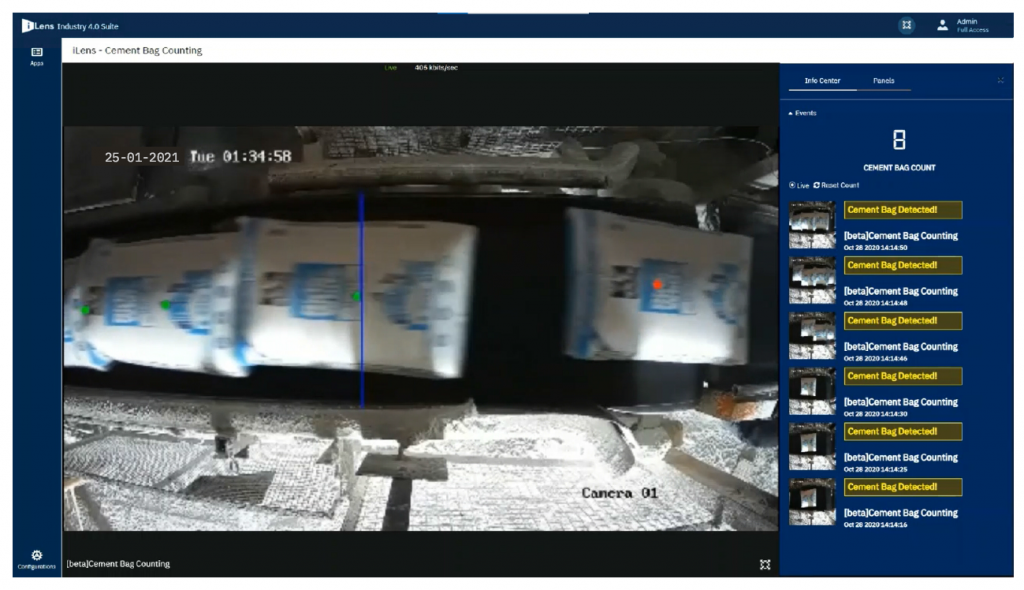

The iLens– Industry 4.0– Vision Analytics- Cement Bag Detection & Counting solution offered 100% accurate & reliable implementation success for our client. The absolute power of the AI Powered solution to accurately detect and count cement bags, even in abnormal cases of conjoined jobs, is its unique premise.

The solution’s inbuilt AI algorithms factor the bags’ attributes, the type and speed of the conveyor belt, truck / wagon loading machinery installed on the plant’s multiple line bays to count every bag loaded.

- AI powered Vision Analytics enabled Cameras mounted across the conveyor belt of multiple line bays where cement bags are dispatched.

- Proactive Alerts, Intelligent Dashboarding on displays and reporting with live insights.

- Number of bags loaded per shipment (and missed bags, dropped bags across the conveyor belts).

- Start/end time duration of each shipment/ operation.

- Numbers and performance per loading line (counts, missed bags, average time per loading, etc.)

- Erroneous operations of bag mismatches in Packing and Loading sections.

- Statistics per loading line/shift.

- Live video feed streamed to Industry 4.0 solution prebuilt with AI/ Machine Learning models to perform accurate detection and reliable counting of the bags.

- Reports are further published on a daily/ consignment basis to the designated floor in charge.

- The solution provides an additional option to integrate with the customer’s ERP to automatically exchange information about the number of bags associated with the loading/ purchase order.

Business Outcomes:

- Highest satisfactory score by customers of the Cement Manufacturer, in delivery of exact purchase order.

- 1.8 Cr INR Savings in 1 Plant, in Loading operations which could be reinvested in raw materials procurement.

- 35-40% reduction in Turnaround Time of loading, counting and dispatch processes.

- Detection and counting of conjoined bags.

- Elimination of manual counting of bags & logging of records leading to decreased human errors and fraud by 80%.

Why Choose Knowledge Lens?

- New-age solution provider leveraging AI-based Vision Analytics, ensuring tamper-proof transport & dispatch of cement bags.

- Proven industry leader with 100% accuracy; the solution has been successfully deployed at one of India’s leading Cement Plants.

- Flexible to be deployed locally or on the Cloud, as per the plant requirements.Dynamic and reasonable pricing structure.

- Highly scalable plug-and-play solution with simple deployment and minimal cabling, as compared to other solution vendors in the market.

- Modular solution components, allowing for rapid scale up/adaptation to future business requirements.

- Reputed Camera make equipped with IP65 enclosure for dust protection & durability.

At Knowledge Lens, we constantly work towards improving our product technologies, so your business can do more for you. In case you have more questions, feel free to drop me a mail at sneha@knowledgelens.com or contact us here.