Client Introduction & Business Requirement:

Our client is a large US based Industrial Automation Company manufacturing Industrial Controllers. They wanted to eliminate the line stoppage of their Pick & Place machines and activate proactive alerts in case of performance deviations in their nozzles.

Their Pick & Place machines extract components from flowing ribbons, known as Tape & Reel and place them accurately on the PCB. Each machine can hold up to 400 nozzles, which are programmed to perform the function of extract (via suction/vacuum) and place for each PCB. The nozzles are primarily designed to accommodate suction and placement of components.

They needed a solution to provide insights from the data while in production, and to notify technicians about potential anomalies in the machine. Nozzle drifts cause rejects which results in raw material wastage and line stoppage, thus impacting productivity loss.

Solution Overview:

- Solution was implemented to consistently monitor and track nozzle performance and generate alerts upon deviation from the desired/designed performance metrics thresholds. The solution was enabled on Web as well as on a Mobile App to track nozzle performance (fluctuations/anomalies) in real-time.

- For the Pick & Place machines line, we provided an end-to-end solution for data acquisition from OEM machines across the globe. It also provided these essential capabilities:

- Data Processing Platform on the Cloud.

- AI/ML Predictive Algorithms for Nozzle Deviation predictions.

- Mobile Applications for Shop Floor Operators and Managers.

- Alert Notifications using SMS and Emails.

In this manner, we deployed the solution for Edge Device Management and Containerized application deployment on the Edge.

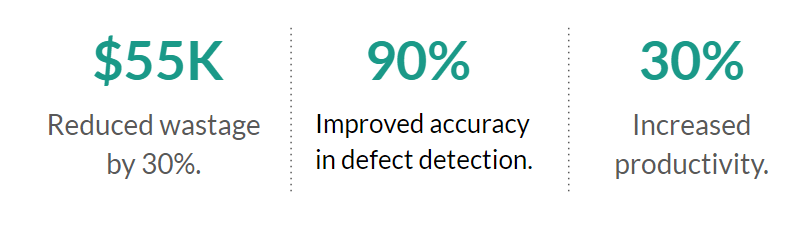

Business Impact:

Concluding Remarks:

At Knowledge Lens, we constantly work towards improving our product technologies, so your business can do more for you. Visit us here to learn more about our products & solution offerings.