The introduction of real-time pollution monitoring systems has started a new era of compliance check in India. A new set of challenges around operation and maintenance have emerged. However, this promises to be a good sign – a step ahead in the right direction.

Real-time pollution monitoring and reporting was a much sought after solution to catapult the environmental governance system in India. Large-scale industries such as Steel and Cement have been monitoring pollution as per the agreement under the charter on Corporate Responsibility for Environmental Protection (CREP), 2003. However, this monitoring was limited to industry use; online reporting to regulators, and data use for compliance check was never a part of it.

In February 2014, the Union Ministry of Environment, Forest and Climate Change (MoEFCC) and the Central Pollution Control Board (CPCB) initiated the use of real-time monitoring for industries in India for the first time. The Continuous Emission monitoring System (CEMS) and the Continuous Effluent Quality Monitoring System (CEQMS) were mandated in 17 categories of highly polluting industries and common pollution treatment facilities. Continuous effluent quality monitors were mandated in grossly polluting industries and those located in the Ganga Basin. Although directions for installation were given, there was an absence of guidelines, instructions, training and knowledge base, making the journey a futile one. Regulators and industries alike, have been struggling hard to set things right.Multiple challenges are faced, but one thing that certainly made a difference is the serious approach with which industries now regard the environment. This is a big change.

Multiple challenges are faced, but one thing that certainly made a difference is the serious approach with which industries now regard the environment. This is a big change.

Conventional system with no credibility left

Conventionally, industries are required to get pollution monitoring done at least monthly by NABL and or EPA accredited laboratories. The report compiled quarterly, is submitted to the respective State Pollution Control Board (SPCB) or Pollution Control Committee (PCC). Many SPCBs/ PCCs have adopted an online consent management system where industries can report pollution monitoring data on a monthly basis. Compliance check is however, carried out on a quarterly basis against the stipulated norms. Currently, the compliance check system uses manual lab- based sample collection and monitoring which can be produced as legal evidence, if required. Section 21 of the Water (Pollution Prevention and Control) Act, 1974, Section 26 of the Air (Pollution Prevention and Control) Act, 1981 and Section 11 of the Environmental (Protection) Act, 1986 stipulate this system of compliance check. With time, while pollution issues became critical, the scale of industrial activities multiplied, the stipulated norms became more stringent, and the existing system of compliance check failed to keep tabs on it.

The conventional system enables regulators to observe the pollution data only once every three months- or in some cases- monthly, and then take any action. By this time, no opportunities are left for the efficient control of pollution. The biggest problem with this system is the credibility of pollution monitoring which is carried out by a third party laboratory hired by the industry itself. Industries have regularly produced manipulated data to show environmental compliance, leaving no room for faith in the system

False compliance not only harms the formulation of suitable policies, it restricts opportunities for improvement for industries, and fuels public agitation.

Introduction of real time monitoring system holds the potential to control the issue of manipulation, if implemented properly.

Initial challenges in implementation

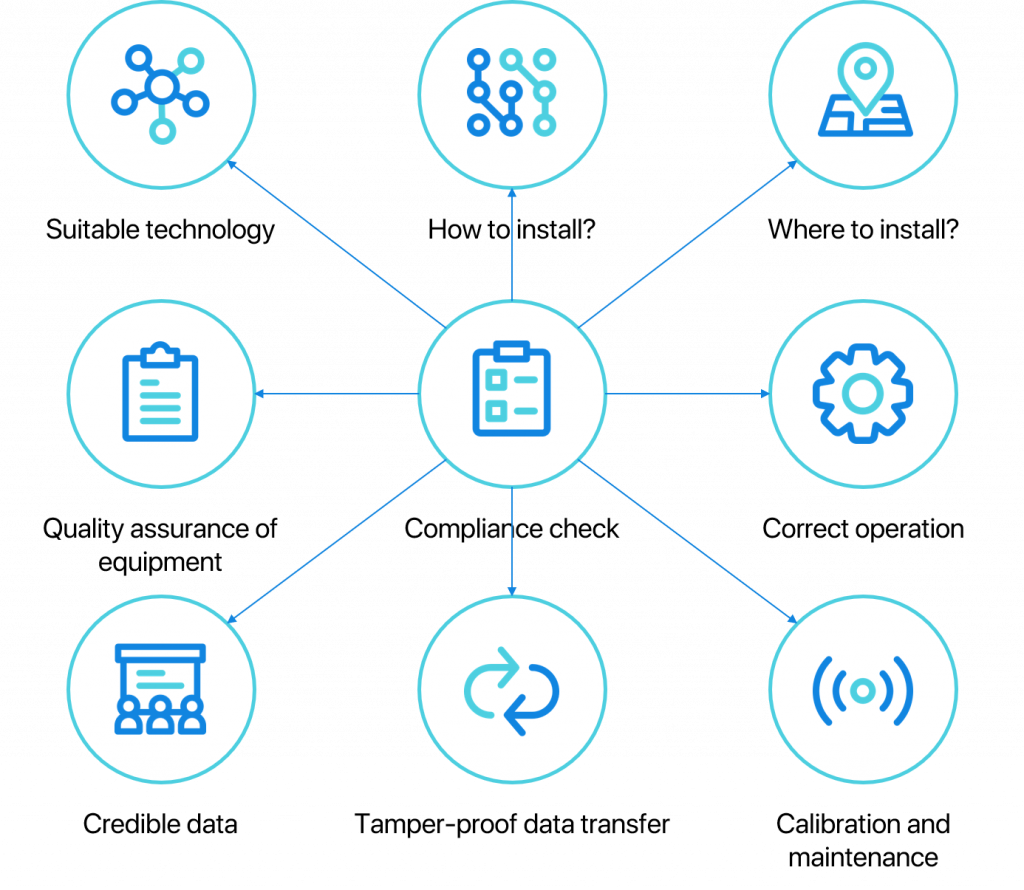

The initial phase of real-time monitoring implementation faced multiple problems, mostly with regard to the lack of information on this technology. These included technology selection, correct installation, proper operation and maintenance, tamper-proof data transfer etc.

Wrong technology selection and incorrect installation of analysers lead to wrong measurement. Similarly, absence of proper calibration and maintenance ends up in inaccurate data. Many experts and ground surveys brought up these issues prevalent among the industries. With time, the guidelines were developed, and stakeholders gained knowledge and experience about the technology. This helped to improve the situation; however, a large number of industries are yet to take sufficient steps to overcome these problems.

Two issues that are related to infrastructure availability- development of indigenous certification system and the laboratory empanelment system for real-time monitors need policy makers’ intervention, and are still in progress. The absence of indigenous certification systems allowed substandard and non-quality assured equipments to flourish in the market. At the same time, empanelled and expert laboratories, proper calibration and performance test of equipment also got by-passed, leading to inaccuracy in the monitoring.

Hurdles ahead

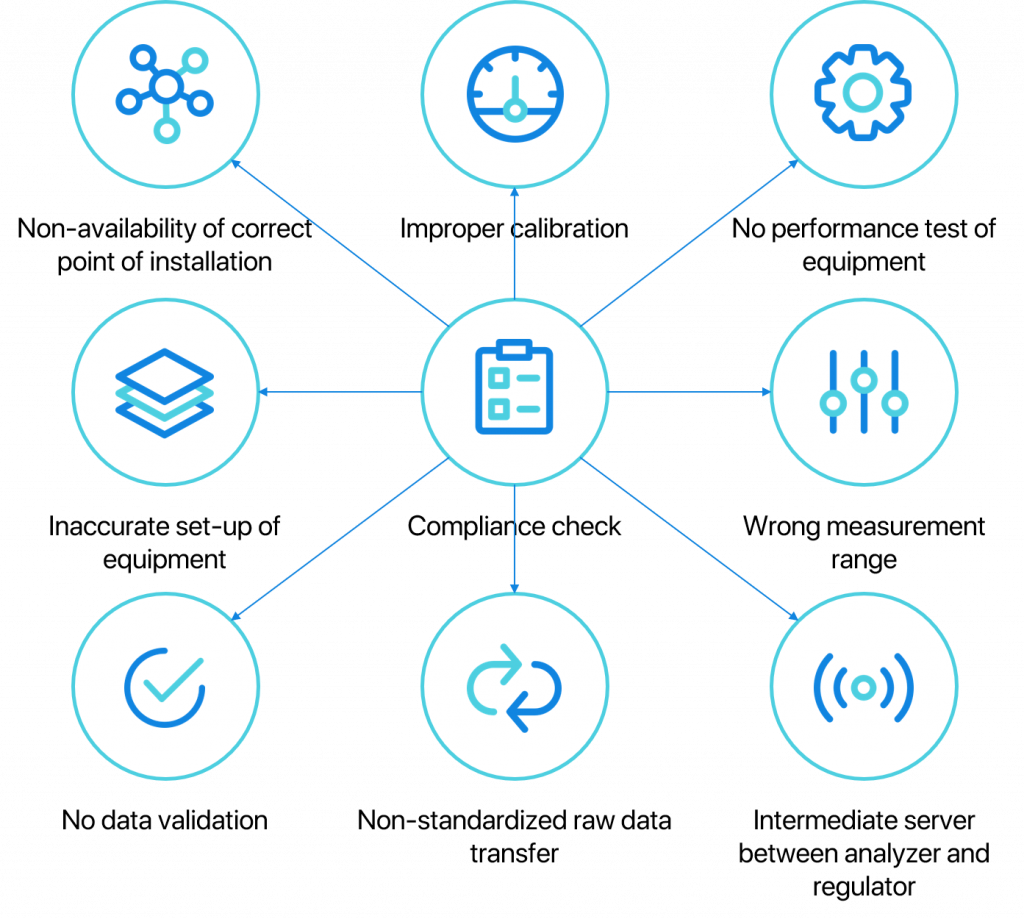

Now that most of the 17 categories of highly polluting industries and GPIs have adopted and experienced real-time monitoring, a new set of challenges have emerged, mostly relating to correct operation and maintenance. Emerging challenges that industries face include improper calibration and performance test of equipment, unavailability of correct installation point, inaccurate set-up of equipment, wrong measurement range selection, intermediate server for data transfer and reporting of incorrect and non-standardized data.

Expert audits of the site uncovers these challenges. In majority cases, the industries and even the vendors at site, are not aware of the problems which ultimately lead to incorrect monitoring and inaccurate data.

The new set of challenges are complex, but also indicate how we are moving a step forward in the right direction. However, it is important for industries to work on these issues and get them resolved soon.

Time to act swiftly

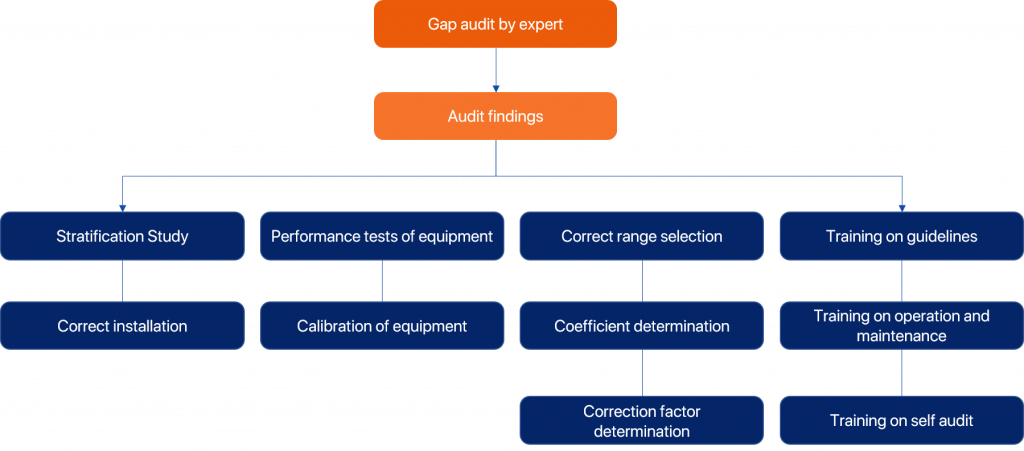

The most important step would be to realize the problems that require expert audit of the site. Such an audit will help to recognize the issues and possible solutions. Since these problems are related to operation and maintenance, a superficial observation wouldn’t help. It requires a deep dive to examine minute details. Qualified industry professionals can get trained and carry out inhouse audits later on. The findings of the audit will guide the next course of action.

Photo credits: Sanjeev K Kanchan

In case of absence of the right point of installation, stratification can be carried out, the most possible point of installation can be chosen, and a correction factor can be applied with the regulator’s permission. For faulty measurement, experts may advice to carry out full calibration, performance tests and correct set-up of equipment. Audit observation can also disclose if the raw data requires correction to bring in to the standard format.

Training must be an essential part of the solution, so that industry officials know about the issues, correct guidelines, proper operation and maintenance, and correct data analysis and transfer. Credible data availability is a win-win situation for both industry and regulators.

As industries ensure better compliance with the regulations and better life of equipment, they will also have opportunities to optimize the process, save on operational costs and improve the overall efficiency. Accurate data will help regulators to rightly recognize the effort of industries and implement adequate regulations. Improved data quality will encourage policy makers to bring regulatory amendments to use real-time data for compliance check. This will also pave the path for market- based pollution control mechanisms such as emission trading schemes, where efforts of industries will be evaluated and compensated properly.

2 Comments

oprolevorter · June 25, 2019 at 12:34 pm

Hey there! Someone in my Myspace group shared this website with us so I came to look it over. I’m definitely enjoying the information. I’m bookmarking and will be tweeting this to my followers! Superb blog and terrific design.

Sneha Mary Christall · June 26, 2019 at 9:38 am

Thank you very much, keep visiting our blog for more updates!